Description

WINGGLER & CENTER FINDER SET

• ITEM CODE NO. ABM-EPT-8705

• These sets are fast effective way of locating the Working center on lathes, bench drills and milling machines.

• Hardened steel points and contacts ensure accurate location.

• The four attachments snap fit into the chuck without removing the collet nut and reducing down time. 5 pieces set imperial

• 5 pieces set imperial

• Chuck with 4 arms.

• Comes in attractive plastic pouch.

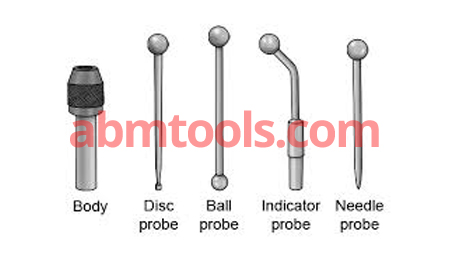

• Set consists of Snap in Holder, Needle Point Attachment, Ball Contact Attachment, Disc Contact Attachment and Off Set Indicator Holder.

The wiggler body holds the selected probe. Loosen the knurled nut and snap the ball on the end of the probe into the body. Tighten the knurled nut so the probe is not loose, but can still move. When using the dial indicator probe, tighten it firmly. Put the shank of the body into the chuck, end mill holder or collet on your mill or drill press.

Use the point probe to find a point on a work piece. This is the probe you use to locate scribed lines on a work piece under the drill or mill chuck. Center the probe by turning on the machine to about 1000 RPM. Use a wooden pencil or other object to press on the side of the probe near the point until it turns true, with no wobble. When you press too hard you will find out why this device is called a wiggler. Once you have the probe centered, turn off the power and center the mark on the work piece under the point of the probe.

Use the disk probe to find the edge of a work piece. The disk on the end of this probe is 0.100” in diameter. Center the probe by turning on the machine to about 1000 RPM. Use a wooden pencil or other object to press on the side of the probe near the point until it turns true, with no wobble. Leave the power on as you move the side of the work piece into the tip of the probe. When the probe touches the side of the work piece it will start to wobble. The center of the spindle is 0.050” from the edge of the work.

Use the ball probe to find the center of existing holes. Center the probe by turning on the machine to about 1000 RPM. Use a wooden pencil or other object to press on the side of the probe near the point until it turns true, with no wobble. Once you have the probe centered, turn off the power and center the existing hole in the work piece under the ball of the probe. This probe can also be used to find the edge of a work piece. The smaller ball on this probe is 0.250” in diameter, so when it touches the side of the work piece, the center of the spindle is 0.125” from the edge of the work.

Use the indicator probe to mount a dial test indicator. Use a dovetail clamp or a body clamp to attach the dial test indicator to the indicator probe. You can use this to check the alignment of a vise on your mill.